Bearing Units

(2314)Our range of bearing units for industrial use

Our bearing unit range offers a wide variety of quality solutions designed for various industrial applications. Bearing units combine the bearing and housing into one unit, allowing easy assembly, long service life, and reliable operation even under demanding conditions. They enable precise shaft alignment and are suitable for both standard and demanding applications in industrial production, agriculture, and transport.

Trusted bearing unit manufacturers

At M&M Intercom, we work exclusively with renowned manufacturers who guarantee top quality and traceability. Our range includes bearing units from: Asahi, Beco, Craft, Dodge, Fafnir, FAG, FK, FKL, FYH, HFH, IKL, INA, ISB, JIB, KDF, Koyo, Linkbelt, Movex, Nachi, NSK, NTN, Peer, PFI, PTI, RHP, Sealmaster, SKF, SNR, Timken, YNT, ZEN, and others. This allows us to offer our customers a wide selection of solutions – from standard to specialized applications.

Dimensions and technical specifications of bearing units

Our offering includes bearing units in various dimensions and designs, ensuring optimal adaptation to each application:

- Length: from 60 mm to 490 mm

- Thickness: from 20 mm to 150 mm

- Height: from 11.5 mm to 285 mm

- Distance between mounting holes: from 32 mm to 380 mm

This wide range of dimensions ensures that the right solution can be selected for any type of shaft and structure. Several housing types are also available (round, square, oval, etc.), providing better adaptability to spatial limitations and design requirements.

Types and designs of bearing units

To cover industrial needs completely, we provide different designs of bearing units:

- Bearing inserts – interchangeable inserts forming the basis for various housing types

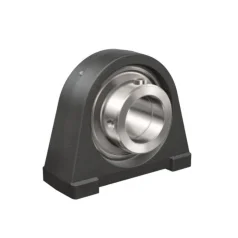

- Pillow block bearing units – designed for mounting on surfaces requiring stability

- Flanged bearing units – for wall and structure mounting, available in round, square, and oval shapes

- Tensioner bearing units – allow adjustment of shaft or belt drive tension

- Cartridge bearing units – compact solutions for installation in special housings

- Bearing units with set screw – simple shaft attachment with screws

- Hanger bearing units – special design for suspended mounting

- Bearing unit covers – additional protection against dust, moisture, and mechanical damage

Each design has its specific advantages, enabling us to provide optimal solutions for every application – from general industrial use to specialized machinery.

Advantages of using bearing units

Bearing units are designed to simplify installation and reduce maintenance time. Their main advantages include:

- Simple and quick installation

- Complete unit with bearing and housing

- Reliable performance under demanding conditions

- Long service life thanks to high-quality materials

- Versatility across different industrial sectors

As many bearing units are equipped with seals and lubrication fittings, they also provide additional protection against dirt, moisture, and external influences.

Use of bearing units in different industries

Our bearing units are applied across numerous industries:

- Manufacturing and logistics: conveyors, automated lines, trolleys

- Agriculture: tillage machines, harvesters, transport machinery

- Construction and transport: mobile equipment, cranes, construction machines

- Food and pharmaceutical industry: production lines requiring hygiene and corrosion resistance

- Paper and wood industry: woodworking machines, saws, paper machinery

- Mining and heavy industry: conveyors, rock crushers, pumps, and fans

Each industry has specific technical requirements, so we offer a wide range of materials and designs.

Seals and internal radial clearance

When selecting bearing units, it is important to also consider additional technical parameters:

- Seals: many units have contact seals on both sides, providing extra protection against dust, moisture, and impurities.

- Internal radial clearance: available in versions with increased clearance (C3, C4) or normal clearance (CN), allowing adaptation to loads, temperatures, and rotational speeds.

Why choose bearing units from M&M Intercom

At M&M Intercom, we combine a wide network of manufacturers with many years of experience in industrial equipment. Our bearing units are not just quality products but also solutions that save customers time and reduce maintenance costs. We provide expert advice, technical support in selection, and fast delivery. Whether you are looking for standard sizes or special designs, we help you find the right solution.

Frequently Asked Questions

1. What are bearing units and what is their role? Bearing units combine the bearing and housing into one assembly. They allow easy installation, precise shaft alignment, and reliable operation in various industrial applications, from manufacturing to transport.

2. What types of bearing units are available? There are various designs: bearing inserts, pillow block bearing units, flanged bearing units, tensioner bearing units, cartridge bearing units, bearing units with set screw, hanger bearing units, and bearing unit covers. Each type is adapted to specific use.

3. Which bearing unit manufacturers are offered by M&M Intercom? We supply products from renowned brands such as Asahi, SKF, FAG, INA, NSK, NTN, Timken, Koyo, SNR, RHP, Sealmaster, ISB, Nachi, PFI, PTI, ZEN, and many more, ensuring a wide choice of standard and special solutions.

4. What bearing unit dimensions are available? We offer a broad range: length from 60 mm to 490 mm, thickness from 20 mm to 150 mm, height from 11.5 mm to 285 mm, and distance between mounting holes from 32 mm to 380 mm. This allows adaptation to different designs and loads.

5. What do CN, C3, and C4 markings mean for bearing units?

These indicate internal radial clearance:

- CN – normal clearance, standard for most applications

- C3 – greater clearance, suitable where bearings heat up in operation (high speed, high load)

- C4 – even greater clearance, for extreme conditions and special applications

If clearance is too small (e.g. CN instead of C3), the bearing may overheat due to friction, shortening service life. If too large (e.g. C4 where CN is enough), vibration, reduced precision, and faster wear can occur.

6. Are bearing units protected against dust and moisture? Yes, many units have contact seals on both sides, protecting against dust, moisture, and impurities. This extends service life and reduces maintenance needs.

7. What are the main advantages of using bearing units? Advantages include easy installation, reduced maintenance time, long service life, reliable operation under demanding conditions, precise shaft alignment, and versatility across industries

8. In which industries are bearing units most commonly used? Bearing units are used in many sectors: manufacturing and logistics (conveyors, automated lines), agriculture (harvesters, tillage machines), construction and transport (machines, cranes), food industry (stainless steel units), automotive industry, mining and heavy industry, paper and wood industry, etc.

9. What is the typical service life of bearing units? Service life depends on proper selection, load, speed, temperature, lubrication, installation, alignment, and maintenance. With proper use and care, bearing units often last more than five years of continuous operation.

10. Does M&M Intercom provide assistance in selecting the right bearing unit? Yes, we provide expert advice and technical support. We help with selecting the right manufacturer, dimension, seal type, internal clearance, and design based on specific operating conditions.

Email: [email protected]

Phone: +386 1 29 27 960

With years of market presence, expertise and experience, we find the most appropriate and cost-effective technical solution for your application.

Custom-made seals with precision up to 0.1 mm for all industries. High-quality materials, adaptable shapes, and fast execution. Solutions for extreme conditions.