Seals for Effective and Long-lasting Protection of Industrial Systems

(11899)Seals are one of the key mechanical components that ensure the safe, reliable, and clean operation of industrial equipment and machinery. Their primary function is to prevent leakage of fluids or gases and to protect against contamination from dirt, moisture, dust, and other harmful environmental influences. They also play a crucial role in reducing wear, noise, and heat loss.

At M&M Intercom, we offer more than 10,000 different types of seals to cover a wide range of industrial needs—from static to dynamic applications, low-pressure to high-pressure systems, and standard to custom-engineered solutions. Products are sourced from renowned global manufacturers such as Alwin Höfert, Dichta, Kastas, Trelleborg, Garlock, Teadit, Lidering, and others.

Main Types of Seals We Offer:

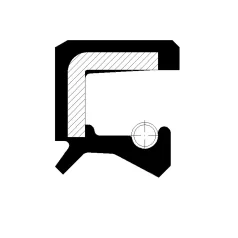

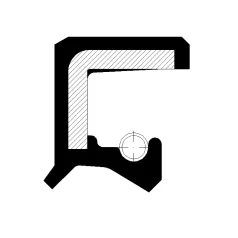

Oil Seals (Semering) and Accessories

most commonly used for sealing shafts in rotary and linear motion. Available in various profiles, materials, and dimensions.

O-rings

a universal solution for static and some dynamic applications. Available in various diameters and materials, resistant to temperature and chemicals.

X-rings

an alternative to O-rings, offering multi-point sealing and better performance at low pressure.

V-rings and Other Axial Seals

provide additional protection for internal sealing components against dirt, moisture, and abrasion.

Hydraulic Seals

designed for high-pressure dynamic applications, wear-resistant and fluid-compatible. Include piston seals, rod seals, wear rings, and seal kits.

Pneumatic Seals

for low-pressure systems where tightness and reliability with fast-moving components are essential.

Mechanical Seals

used for rotating shafts where high sealing performance and thermal resistance are required. Common in pumps, valves, and compressors.

Flange Gaskets

for static applications requiring a complete seal between pipe joints or other components.

Gland Packings

for dynamic and static applications under high temperature or chemical load. Used in valves, pumps, and mixers.

Other and Special Seals

includes flat gaskets, combination seals, graphite-based solutions, and metal-reinforced types.

Quality, Production and Consultation

In addition to a large stock selection, we also offer custom seal production. In our machining center, we manufacture seals to your specifications using appropriate materials and within the shortest possible time.

Proper selection, installation, and maintenance of seals are critical. Their performance depends on material resistance (temperature, chemicals), elasticity, tensile strength, and pressure on the sealing surface. Dynamic seals often require proper lubrication for optimal performance.

A Reliable Partner for All Industrial Sectors

Whether you work in manufacturing, processing, the energy sector, food industry, mechanical engineering, or maintenance—we have the right solution. M&M Intercom not only provides products but also expert support, technical consultation, and fast response.

With years of market presence, expertise and experience, we find the most appropriate and cost-effective technical solution for your application.

Custom-made seals with precision up to 0.1 mm for all industries. High-quality materials, adaptable shapes, and fast execution. Solutions for extreme conditions.