Belt cutting and welding – precision service tailored to your needs

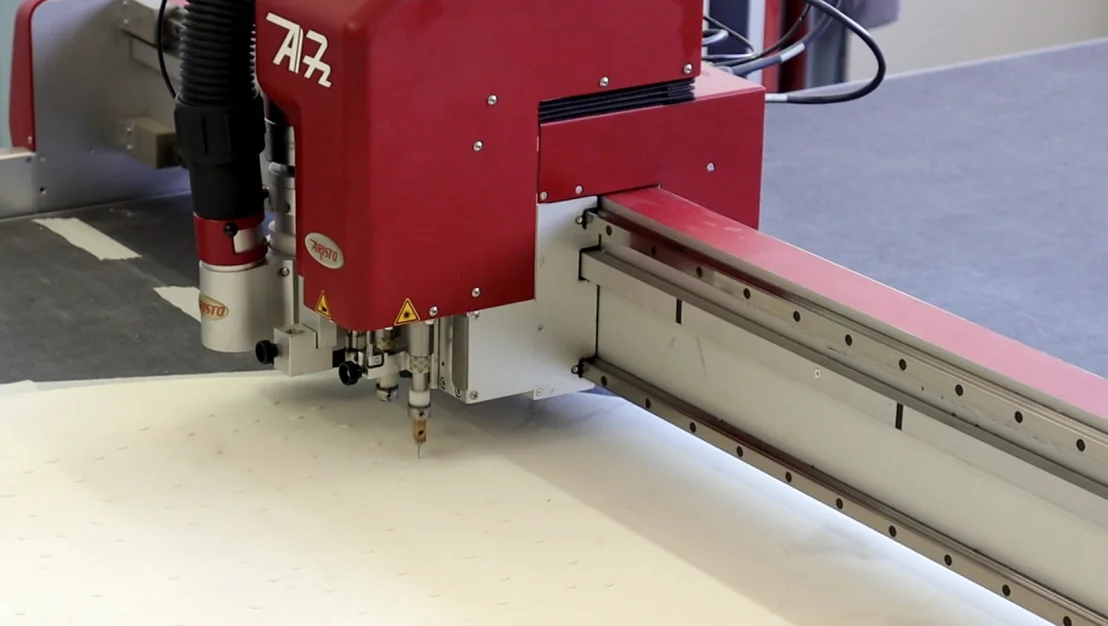

COMPLETE FLEXIBILITY IN BELT CUTTING

At M&M Intercom we provide highly precise belt cutting, fully adapted to customer requirements. Our advanced cutting machine delivers accuracy up to 0.2 mm, enabling us to prepare belts in any width the same day the order is placed.

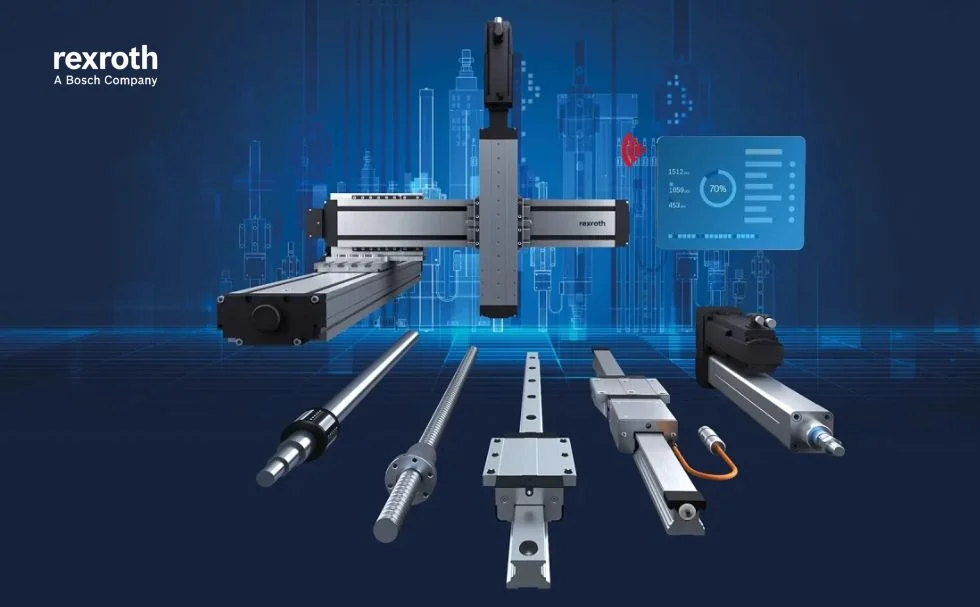

We cooperate with world-renowned manufacturers such as Megadyne, Optibelt, Bando, Hutchinson and PIX ensuring high-quality industrial belts for a wide range of applications.

Cutting lengths range from 130 mm to 7800 mm, and widths up to 750 mm. The machine guarantees accuracy of cuuting for timing, ribbed and flat belts. The process includes tension shaft adjustment, cutting angle alignment, and stable sleeve tension control.

A special feature is the floating knife with a guiding pulley, which follows rib with absolute precision during the cutting of ribbed (micro) belts. This ensures a 100% accurate cut, full functionality, and high-quality results.

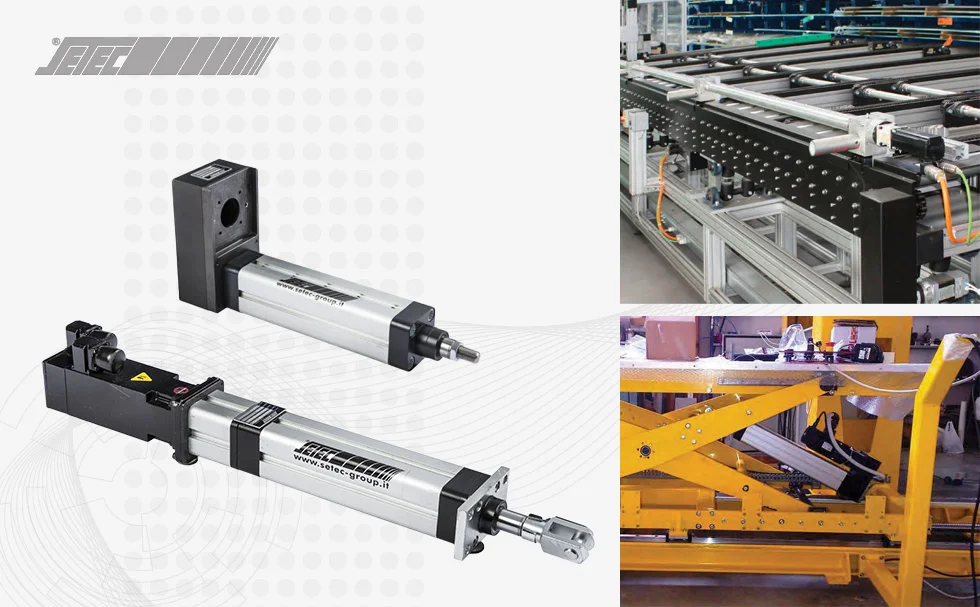

OEM-QUALITY BELT WELDING

In addition to cutting, we also provide premium belt welding services, delivering 100% joint strength and long-term reliability.

Our state-of-the-art Megadyne welding machine enables automated and precise welding of PU belts of different profiles and sizes, including those with special coatings such as PAZ, PAR, NFT, and NFB.

The system includes:

- pre-set welding programs for different belt types,

- separate control of upper and lower plate temperatures,

- precise adjustment of pressure and welding time,

- water-cooling system for material stabilization after processing.

The welding service covers polyurethane timing belts in profiles T, AT, HTD, RPP and imperial profiles.

RESPONSIVENESS, QUALITY, AND SUPPORT COMBINED

We know that in industrial processes, every hour counts. That is why M&M intercom provides cutting and welding fast service and reliable execution and quality.

Most orders are completed within 24 hours, tailored to customer requirements. Our technical team advises on the most suitable belt selection and provides complete support throughout the process.

VERIFIED QUALITY FROM LEADING MANUFACTURERS

We supply belts only from trusted global brands:

- Megadyne

- Optibelt

- Pix

- Bando

- Hutchinson

On request, we also provide alternative solutions from Gates, Contitech, Elatech, Brecoflex, and others.

Every belt we cut or weld comes from a verified supply chain, suitable for industries where precision and reliability are essential.

WHY CHOOSE US?

- Professional consulting and individual approach

- Fast processing and delivery times

- Custom width, length, and shape adjustment

- OEM-quality PU belt welding

- In-house technological park and experienced team

E-mail: [email protected]

Telefon: +386 1 29 27 960

Frequently Asked Questions

1. What cutting accuracy do you guarantee for belts?

With our advanced cutting machine, we guarantee belt cutting accuracy up to 0.2 mm. This allows complete customization to your specifications – regardless of whether the belt is timing, ribbed, or flat.

2. How quickly can you deliver custom-cut belts?

In most cases, we can deliver the cut belt the same day, provided the order is placed by a certain time. Our semi-automatic system ensures fast processing without compromising quality.

3. Which belt manufacturers are included in the service?

We work with the world’s top manufacturers such as Megadyne, Pix, Bando, Hutchinson, and Optibelt. All belts meet the highest industry standards for cutting and welding. We also collaborate with other brands like Gates, Contitech, Breco, Elatech, and Mulco.

4. What is the quality of the weld for welded belts?

We guarantee 100% joint strength, as we use a fully automated Megadyne welding machine with precise temperature, pressure, and time control. The result is PU belts with OEM quality, ready for demanding applications.

5. Which types of belts can you process and weld?

We process and weld various types of belts: timing, ribbed (micro/Poly-V), flat, as well as special belts with coatings such as NFT (PAZ), NFB (PAR), and Linatex. Our process is fully adaptable to technical requirements and applications.