Motovario Assembly Center (MAC) – fast, reliable, and certified gearbox assembly

OFFICIAL MOTOVARIO MAC CENTER – THE HIGHEST STANDARDS OF ASSEMBLY, QUALITY, AND TRACEABILITY OF GEARBOXES

Motovario Assembly Center (MAC) is an officially certified assembly center of Motovario S.p.A., a member of the TECO Electric & Machinery Co. group, one of the world's leading manufacturers of mechanical reducers, electric motors, and drive solutions. As an authorized Motovario partner, we perform professional, fast, and technically flawless assembly of standard gearboxes using exclusively original Motovario components, which guarantees end users factory quality, complete traceability, and an official warranty.

Our MAC center is designed as a local extension of the Motovario factory in Italy, which allows us exceptional flexibility, short delivery times, and direct access to technical data, configurations, and spare parts.

What is a MAC center?

As an authorized Motovario MAC center, we provide:

- authorization for local assembly of gearboxes using original Motovario components

Assembly is carried out exclusively using certified parts that comply with factory requirements. - Officially trained personnel with access to the MAC Soft configuration system

MAC Soft allows for complete configuration of gearboxes according to customer specifications. - Permanent stock of original Motovario spare parts

We have a stock of key components for the H, B, S, BA, HA series and worm gearboxes. - Technical support directly from the Motovario technical department in Italy

This ensures accuracy, traceability, and immediate resolution of complex requests.

MAC centers around the world are designed as an extension of the factory, enabling fast supply, local assembly, and the highest level of technical reliability.

Advantages of the MAC Center

1. Fast assembly and extremely short delivery times

Thanks to our constant stock of components, we can assemble reducers in a matter of hours. Standard configurations are usually available within 24–48 hours, which significantly reduces typical factory lead times of several weeks.

2. Technical flexibility and custom configuration

Each unit is configured according to the customer's requirements: gear ratio, installation position, output shaft type, output flanges, bearing type, seals, and the option of an electric motor. The MAC center thus combines factory precision with complete modularity.

3. Reliability, originality, and complete compatibility

We use exclusively original Motovario components in our assemblies. Assembly is carried out according to strict factory procedures, ensuring:

- Complete repeatability of quality

- High efficiency

- Minimal wear

- Reliable operation even in demanding industrial conditions

4. Factory warranty and traceability

Each assembled gearbox receives an official Motovario warranty, identical to factory-made units. The units are registered, with a unique serial number and complete traceability from component selection to final assembly.

5. Professional technical and service support

Our team is certified by the Motovario factory in Italy. We offer:

performance diagnostics

- advice on the selection of gear ratios

- support for integration with electric motors

- service and maintenance

6. Optimization of logistics and supply chain costs

Local assembly eliminates the need for large safety stocks of end units. This means:

- lower logistics costs

- fewer delays due to customs clearance

- shorter time window between ordering and installation of the gearbox

7. Option of assembly with electric motors

We offer complete Motovario drive units: gearbox + electric motor.

Also available on request in:

- ATEX versions

- IE3 and IE4 efficiency classes

- Combinations for special industrial applications

This combination ensures less administration, faster project implementation, and optimal matching of the motor and gearbox.

GEARBOX OFFER

Our MAC center enables fast, flexible, and technically flawless assembly of a wide range of Motovario gearboxes from original components. Below we present the key series that we assemble, configure, and test locally in accordance with the highest factory standards.

H SERIES CAST IRON GEARBOXES

The Motovario H (STANDARD IEC) series features robust single-stage, two-stage, and three-stage coaxial gearboxes designed for reliable power transmission, high operating efficiency, and long service life. Their cast iron construction ensures stable operation even in harsh industrial environments where high loads, vibrations or continuous operation are present.

They are used in transport systems, mixing processes, the energy industry, the manufacturing industry, and many other applications where exceptional mechanical reliability is required.

CAST IRON REDUCERS SERIES B

The Motovario B (STANDARD IEC) series combines a compact design and reliable bevel gear drive with high transmission efficiency. It is ideal for applications where angular transmission, reliable operation, and robust construction are required.

They are most commonly used in applications with high dynamic movement, in machine lines, packaging systems, lifts, and transport devices. Their modular construction allows them to be adapted to different needs.

CAST IRON REDUCERS OF THE S SERIES

The Motovario S (STANDARD IEC) series is designed as a shaft-mounted reducer that provides extremely robust power transmission in a wide range of industrial applications. Reliable operation in harsh conditions, easy installation, and high load capacity are the main advantages of this series.

These gearboxes are often used in the concrete industry, woodworking industry, on conveyors, filling stations, and other process lines where durability and reliability are key.

HA SERIES CAST IRON GEARBOXES

The Motovario HA series combines an aluminum housing with the reliability of coaxial gearboxes. It is characterized by low weight, excellent mechanical stability, and a wider range of installation options, even in structurally limited spaces.

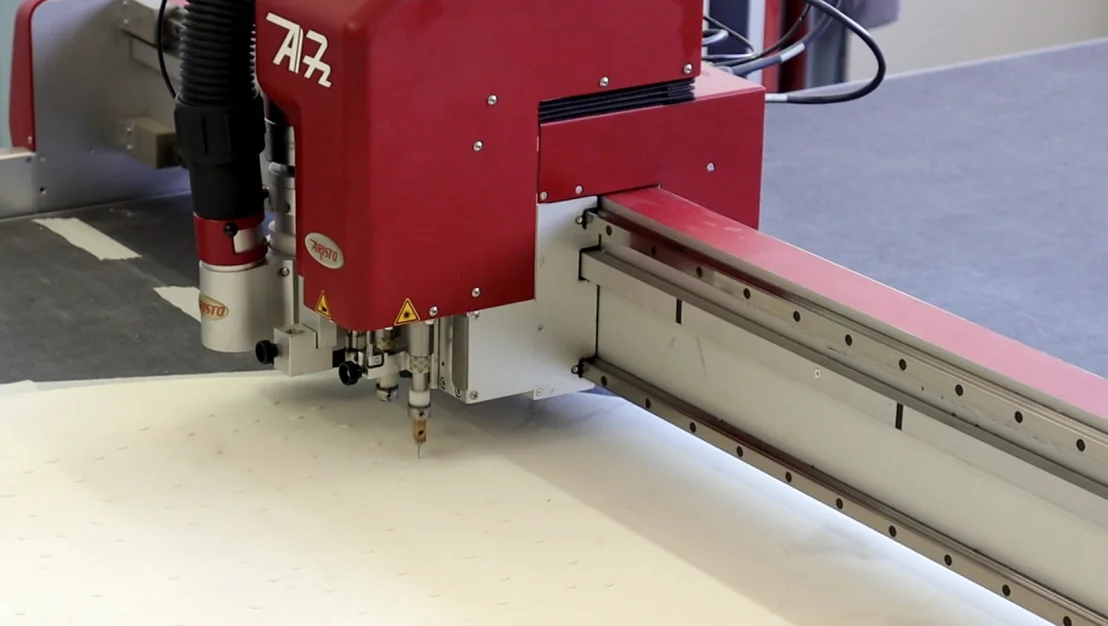

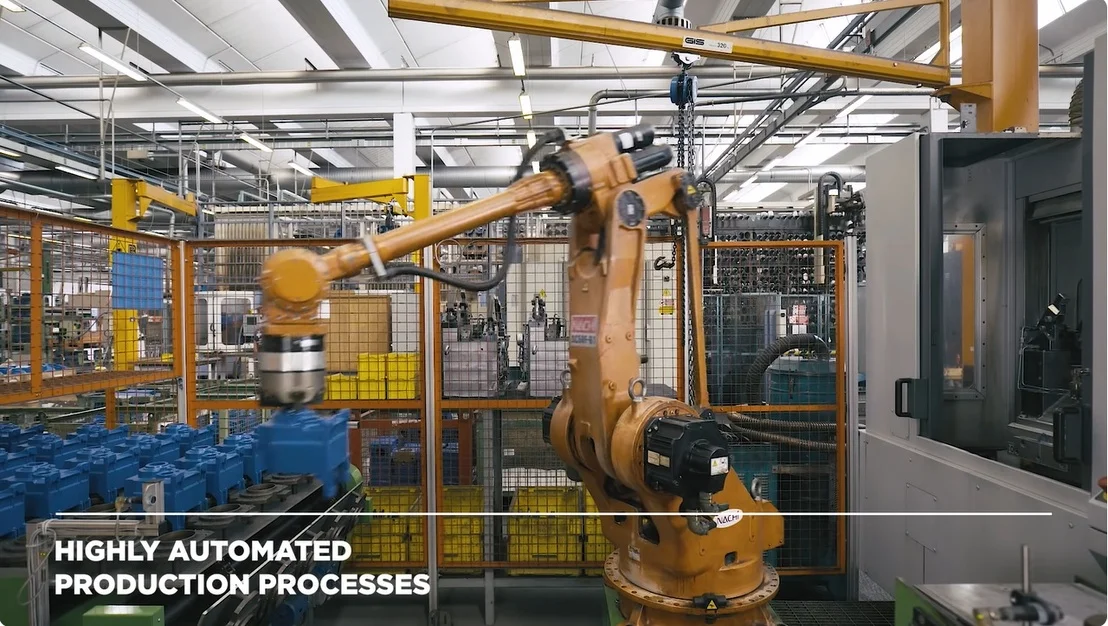

Their exceptional flexibility makes them ideal for applications where lightness and quiet operation are important, such as the food industry, pharmaceuticals, logistics systems, and automated production.

BA SERIES CAST IRON REDUCERS

The Motovario BA series features compact right-angle gear reducers designed for high efficiency, modularity, and reliable power transmission. They are suitable for applications with high torque, variable loads, and continuous operation.

They are most commonly found in machines with high reliability requirements, such as packaging systems, the milling industry, logistics lines, and mixing processes.

WORM GEAR REDUCERS AND PRE-STAGES

The NMRV, NMRV-P, NRV, and SW series worm gearboxes are a reliable solution for power transmission with gear ratios from 1:5 to 1:10000. They are characterized by quiet operation, long service life, the option of aluminum or cast iron construction, and high load resistance.

Due to their versatility, they are one of the most commonly used solutions for transport systems, filling stations, lifting mechanisms, light automated lines, and processes where compact, simple, and reliable power transmission is required.

ADVANTAGES FOR CUSTOMERS

At M&M Intercom, we believe that the quality of assembly is just as important as the quality of the components themselves. That is why our MAC center offers key advantages:

- Time efficiency – assembly in a few hours instead of weeks

Local assembly eliminates long factory lead times, enabling rapid integration of the gearbox into your production process. - Solutions from stock – immediate delivery

With a constant stock of key original Motovario components, we ensure a quick response and immediate availability of the most sought-after models. - Flexibility – solutions even for special gear ratios

With the MAC configurator, we enable a completely personalized gearbox design in line with your needs, operating conditions, and design constraints. - Comprehensive service – assembly, testing, oil lubrication, and final testing with an electric motor

Each unit is tested before shipment. Upon request, we also perform final assembly with an electric motor (including ATEX). - Reliability – original parts, factory methodology, expert team

All units are assembled in accordance with strict Motovario standards, ensuring the best possible quality.

NEED HELP OR ADVICE?

For quick processing of your requests, fill out the contact form or write to us at [email protected].

Our team will work with the MAC configurator to prepare the optimal technical solution for you.

Frequently asked questions:

1. How long does it take to assemble a gearbox at the MAC center?

At the MAC center, we offer significantly shorter delivery times than the factory, as we have a constant supply of original Motovario components. Standard gearbox designs can be assembled in just a few hours, and most units are ready for shipment within 24–48 hours. For more complex configurations, the delivery time is slightly longer, but still significantly shorter than factory delivery.

2. Are the gearboxes assembled at the MAC center of the same quality as those from the factory? Yes. Since we use only original Motovario components and follow the official assembly procedures and MAC Soft configurations, the gearboxes are of exactly the same quality and technical compliance as the units assembled in the Italian factory. In addition, they carry the official Motovario warranty and serial traceability.

3. What information is needed to correctly configure a gearbox? For accurate configuration, we need information about the gear ratio, type of application, motor output power, rotation speed, installation position, required torque, output shaft type, flange type, and required protection level. Our team will help you with the selection if any information is missing or unknown.

4. Can you assemble a gearbox together with an electric motor at the MAC center?

Of course. Upon request, we can prepare a complete drive unit that includes a gearbox and an electric motor. We can also supply ATEX motors, IE3 or IE4 efficiency classes, and special designs for specific industrial environments. This avoids mismatched dimensions and reduces installation time at the customer's site.

5. Do you offer technical advice on choosing the right gearbox? Yes, our staff is trained according to Motovario standards and offers comprehensive technical support. We assist with torque calculations, gear ratio selection, load suitability checks, and drive system optimization based on process requirements.

6. What is the warranty for gearboxes assembled at the MAC center? All gearboxes come with an official Motovario factory warranty, just like factory-assembled units. The gearboxes are registered with a unique serial number and entered into the Motovario system, ensuring complete traceability, verifiable materials, and compliance with procedures.

7. Can you also supply gearboxes for heavy or special operating conditions?

Yes. We supply and assemble gearboxes for high torques, high temperatures, corrosive environments, aggressive media, and continuous 24/7 operation. For special requirements, such as potentially explosive environments, ATEX versions and special bearings, seals, and additional modifications are also available.

8. Is it possible to obtain a gearbox in exactly the same configuration even after several years? Yes. Thanks to complete traceability in the Motovario system, each configuration is stored with precise parameters, allowing for repeatability even after several years. This is crucial for the maintenance of machines where identical replacement is necessary for smooth operation.

9. How is the quality of assembly guaranteed at the MAC center?

We guarantee quality by using original components, qualified personnel, official assembly procedures, testing each unit, and direct technical connection with the Motovario department in Italy. In addition, each gearbox is checked for tightness, operation, and correct configuration.

10. Do you also offer maintenance or servicing of gearboxes? Yes, we offer comprehensive service support—from diagnostics, wear inspection, seal and bearing replacement, to complete gearbox refurbishment. In the case of critical applications, we also provide recommendations for optimal maintenance intervals and the selection of appropriate lubricants for a longer service life.

Email: [email protected]

Tel.: +386 1 29 27 960